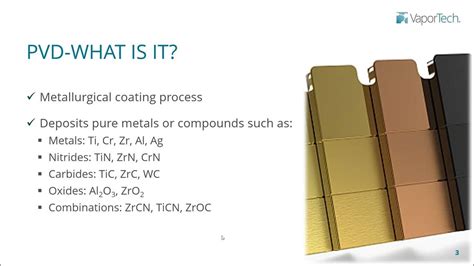

what is pvd fake watch | pvd coating what is pvd fake watch PVD or Physical Vapor Deposition is a special technique used to apply a thin, yet very durable layer of material onto a metal surface. In the world of wristwatches, this material is used to coat the case, bracelet, and some of the other components to give it .

The Rolex Datejust: Popular Variants at a Glance. Rolex Datejust 36: Diameter of 36 mm, available in stainless steel and two-tone versions, Jubilee or Oyster bracelet, fluted, polished, or diamond-set bezel; Rolex Datejust 41: Diameter of 41 mm, available in stainless steel and two-tone versions, Jubilee or Oyster bracelet, fluted or polished bezel .

0 · what does pvd coating mean

1 · pvd gold coating review

2 · pvd coating review

3 · pvd coating for watches

4 · pvd coating fading

5 · pvd coating colors

6 · pvd coating

7 · does pvd fade over time

Discover the Submariner Date watch in Oystersteel and yellow gold on the Official Rolex site. Model:m126613lb-0002 . 3235, Manufacture Rolex. Precision-2/+2 sec/day, after casing. Functions. Centre hour, minute and seconds hands. Instantaneous date with rapid setting. Stop-seconds for precise time setting.

At its core, PVD coating enhances a watch’s looks and durability. The PVD coating process is a meticulously controlled sequence of steps in manufacturing that transforms the .

Want to larn more about PVD coating on watches and how it works? Will PVD scratch and fade over time or is it durable? Learn more here! The PVD coating is Titanium Nitride, which is a durable, gold-toned material. These should hold up better than gold plating, since gold is much softer than TiN, but I would .Personally I don't love PVD, if you're not springing for the real thing it always looks kinda fake, and fake gold just aint it. The other issue is that PVD can wear thin with age and use. It's just a . There are two main options which can be used to coat steel, PVD and DLC coating. In short: PVD or Physical Vapor Deposition, is a process which vaporizes a number of metals, .

PVD or Physical Vapor Deposition is a special technique used to apply a thin, yet very durable layer of material onto a metal surface. In the world of wristwatches, this material is used to coat the case, bracelet, and some of the other components to give it .

At its core, PVD coating enhances a watch’s looks and durability. The PVD coating process is a meticulously controlled sequence of steps in manufacturing that transforms the watch’s surface, providing it with an additional layer of . Want to larn more about PVD coating on watches and how it works? Will PVD scratch and fade over time or is it durable? Learn more here!

prix montre rolex femme en tunisie

what does pvd coating mean

The PVD coating is Titanium Nitride, which is a durable, gold-toned material. These should hold up better than gold plating, since gold is much softer than TiN, but I would expect them to start looking tatty eventually. Personally I don't love PVD, if you're not springing for the real thing it always looks kinda fake, and fake gold just aint it. The other issue is that PVD can wear thin with age and use. It's just a coating on top of the steel. There are two main options which can be used to coat steel, PVD and DLC coating. In short: PVD or Physical Vapor Deposition, is a process which vaporizes a number of metals, and then binds it on a surface, in layers, in a heated vaccuum. DLC or Diamond Like Carbon, is a different way to use the PVD process. Speaking in the simplest terms, the PVD coating process refers to the application of an extremely thin layer of material onto the surface of components that need to be protected from corrosion and other kinds of damage. The most common coating materials are titanium, aluminium, and gold.

Chances are if you're looking at a PVD gold watch you're looking at a watch coated with titanium nitride and not gold at all. If you use gold I think think the coating would be so thin (2-3 microns) and so soft it's lifespan would be measured in months.A material selected to coat a base metal or substrate surface. That material is vaporized and then deposited on the base or substrate material, bonding molecular with the base material. PVD watch coating is very durable and attractive as a watch case and bracelet finish.

Whether it’s a gold PVD coating giving a stainless steel watch the appearance of a solid gold timepiece, or a functional coating reducing friction and wear on the watch’s gears, PVD has transformed the watchmaking industry. PVD or Physical Vapor Deposition is a special technique used to apply a thin, yet very durable layer of material onto a metal surface. In the world of wristwatches, this material is used to coat the case, bracelet, and some of the other components to give it .

At its core, PVD coating enhances a watch’s looks and durability. The PVD coating process is a meticulously controlled sequence of steps in manufacturing that transforms the watch’s surface, providing it with an additional layer of . Want to larn more about PVD coating on watches and how it works? Will PVD scratch and fade over time or is it durable? Learn more here!

The PVD coating is Titanium Nitride, which is a durable, gold-toned material. These should hold up better than gold plating, since gold is much softer than TiN, but I would expect them to start looking tatty eventually. Personally I don't love PVD, if you're not springing for the real thing it always looks kinda fake, and fake gold just aint it. The other issue is that PVD can wear thin with age and use. It's just a coating on top of the steel. There are two main options which can be used to coat steel, PVD and DLC coating. In short: PVD or Physical Vapor Deposition, is a process which vaporizes a number of metals, and then binds it on a surface, in layers, in a heated vaccuum. DLC or Diamond Like Carbon, is a different way to use the PVD process.

Speaking in the simplest terms, the PVD coating process refers to the application of an extremely thin layer of material onto the surface of components that need to be protected from corrosion and other kinds of damage. The most common coating materials are titanium, aluminium, and gold. Chances are if you're looking at a PVD gold watch you're looking at a watch coated with titanium nitride and not gold at all. If you use gold I think think the coating would be so thin (2-3 microns) and so soft it's lifespan would be measured in months.A material selected to coat a base metal or substrate surface. That material is vaporized and then deposited on the base or substrate material, bonding molecular with the base material. PVD watch coating is very durable and attractive as a watch case and bracelet finish.

prix des rolex pour homme

pvd gold coating review

prix rolex gmt master 2 or et acier

pvd coating review

$10K+

what is pvd fake watch|pvd coating